Battery Springs

From consumer electronics to industrial devices, reliable battery contact springs are essential for consistent power delivery, and Lee Spring's Battery Springs are trusted by engineers worldwide. Our comprehensive stock line of conical springs supports every stage of product development—from initial prototyping through full production runs. These economical and proven battery contacts are purpose-built for molded cases with self-contained battery compartments, ensuring secure connections that maintain performance over countless battery changes. Available in various mounting configurations and battery size variations to meet diverse application needs. Lee Spring’s stock line of Battery Springs are conical springs that are perfect for prototype and small run production, as well as larger runs. These economical and reliable battery contacts are ideal for moulded cases with self-contained battery compartments. These battery springs are available in various mounting configurations and battery size variations.

What makes these battery spring contacts reliable?

Our battery spring contacts have been designed to adjust to varying battery lengths and provide low contact resistance and dependable connections.

Which battery sizes do these springs work with?

Each of the four battery contact configurations is designed to work with the four most popular battery sizes: AA, AAA, C, and D.

Stock Battery Spring Material Options

The springs are offered in a choice of two materials: nickel coated music wire or silver coated beryllium copper. If our stock product designs do not meet your requirements, we can provide custom designs for battery springs, fourslide part contacts or stampings.

Nickel Coated Music Wire

Since most alkaline batteries have nickel plated containers, a nickel coating for the metal contacts is suitable. The use of similar material removes the possibility of galvanic corrosion and aids in wear resistance.

What other benefits does nickel coating provide?

Nickel will tend to wipe and aid in breaking down the oxide that can form on the battery metal contact surface. In addition, a nickel coating will provide general corrosion resistance and is an excellent conductor of electricity.

Silver Coated Beryllium Copper

Beryllium Copper is among the hardest, strongest and most wear-resistant of the copper alloys. The silver coating further enhances electrical and thermal conductivity.

How does silver coated beryllium copper compare to other materials?

The electric conductivity is 65-70% that of copper; the strength and fatigue resistance are comparable to higher beryllium alloys. The light silver plating allows for easy soldering. Beryllium copper is corrosion resistant in various environments and is both non-magnetic and non-sparking.

Learn more about spring materials

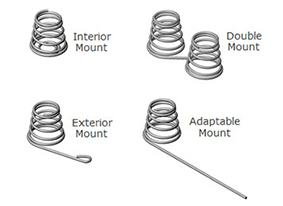

Stock Battery Spring Mounting Configuration Options

Stock Battery Springs are available in a choice of four conical spring configurations:

- Interior Mount - Designed for installation inside battery compartments

- Exterior Mount - Positioned on the outside of battery housing

- Adjustable Mount - Allows for flexibility in positioning and battery size accommodation

- Double Mount- Provides dual contact points for enhanced connection reliability

Which battery spring mounting configuration should I choose for my application?

The choice depends on your specific battery compartment design, space constraints, and connection requirements. Interior mounts work well for compact designs, while adjustable mounts offer the most versatility for varying battery sizes.

Custom Battery Spring Solutions

What if your stock designs don't meet my specific requirements?

If our stock product designs do not meet your requirements, we can provide custom designs for battery springs, fourslide part contacts, or stampings. Our engineering team can work with you to develop solutions tailored to your specific application needs.

Are these springs suitable for both small and large production runs?

Yes, these battery springs are perfect for prototype and small run production, as well as larger production runs, making them versatile for various manufacturing needs and production volumes.

Simply request a custom battery spring quote today or contact a Lee Spring Engineer for design assistance or to answer any questions to help start your custom battery spring project. Lee Spring is ISO 2015:9001 certified, REACH and RoHS compliant and ITAR Registered.

Sign Up/Log In

Sign Up/Log In

.png)