LeeP™ Plastic Composite Springs

LeeP™ is Lee Spring’s response to increased requests for springs that combine the strength of metal with the special attributes of high performance engineered thermoplastics. After years of extensive engineering design and materials research, Lee Spring’s technical team has developed this unique compression spring offering.

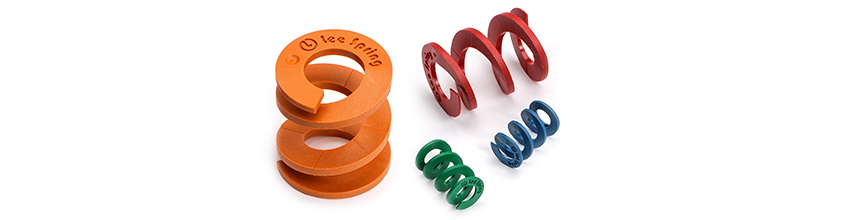

LeeP™ springs are fabricated in distinctive formulations of Ultem* PEI resin, the material of choice for meeting LeeP’s specified criteria. LeeP Plastic Composite Springs are stocked in a variety of standard sizes, each available in a “rainbow” of strengths formulated from different Ultem* resins. The six increasing strengths are easily identifiable by distinct colors: Red, Orange, Yellow, Green, Blue and Violet. For other sizes, resins, or colors, Lee Spring has the advanced technology to provide Custom LeeP™ Compression Springs to meet the most exacting specifications.

Advantages

- Unique patent pending designs to maximize spring rates and cycle life, while minimizing solid height.

- High strength to weight ratios that optimize performance while reducing mass.

- Excellent stability of physical and mechanical properties at temperatures up to 340°F (171° C).

- High corrosion resistance and generally compatible with many chemicals including strong acids, weak bases, aromatics, and ketones.

- Non-magnetic material does not interfere with imaging and other Ferro-sensitive technologies.

- Dielectric insulating material suitable for non-conductive applications.

- Low flammability and toxicity ensuring environmental safety.

- Recyclable and compliant with most Global regulations including RoHS and REACH.

Applications

- Medical products and processing equipment

- Pharmaceutical delivery devices

- Imaging and X-Ray equipment

- Food processing and packaging equipment

- Aerospace products

- Marine products

- Electronics and electrical equipment

- Water Purification systems

- Chemical environments

- Automotive interiors

- Pollution Control systems

- Semi-conductors

- Instrumentation

- Communication devices

- Cosmetics packaging equipment

*Trademark of SABIC Innovative Plastics IP BV.

Sign Up/Log In

Sign Up/Log In

.png)